Logging Wire Rope

In the demanding world of the logging industry, the name of the game is highest strength and longest life. And that’s where Union excels. No matter where the logging operation is in the world, we can deliver tough, compacted, consistent products to our distributors and their end customers.

Our tried and tested forestry ropes are usually peened in order to generate a higher metallic cross section and thus higher breaking forces, and in order to create as smooth a rope surface as possible. In particular in rocky terrain, this offers fewer contact surfaces that can be damaged. The use of peened ropes is also advantageous with multi-layer winding on rope winches. Furthermore, the service life of the rope can be significantly increased by special lubrication which, in particular, substantially reduces friction and corrosion.

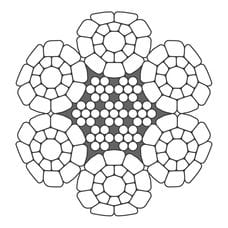

Feature:

- Rope category number (RCN) 04 according to ISO 4309

- Ordinary lay

- Seale construction

- Bright standard

- Special lubrication

- Outer strands compacted

- Zusätzlich einfache Seilverdichtung

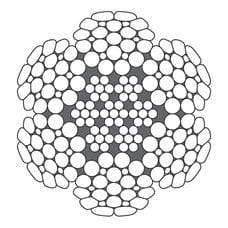

Feature:

- Rope category number (RCN) 04 according to ISO 4309

- Ordinary lay

- Filler construction

- Bright standard

- Special lubrication

- Double rope compaction

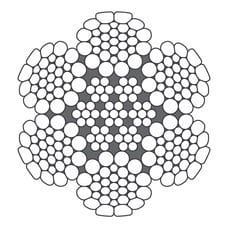

Feature:

- Rope category number (RCN) 08 according to ISO 4309

- Warrington-Seale construction

- Double rope compaction

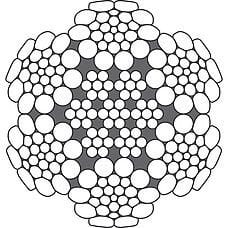

Feature:

- Rope category number (RCN) 06 according to ISO 4309

- Ordinary lay

- Warrington-Seale construction

- Bright standard

- Special lubrication

- Double rope compaction