Elevator Wire Rope from LKS

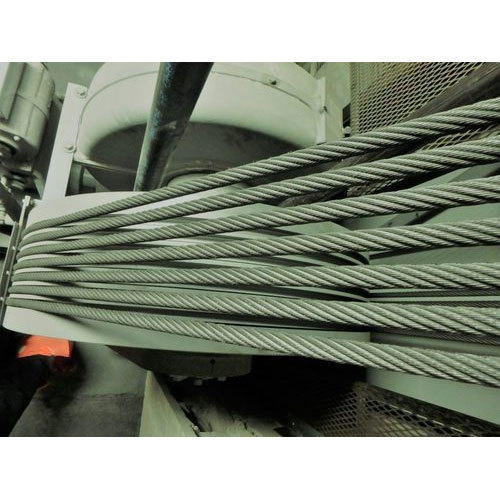

Abstract: the elevator wire rope mainly refers to the traction steel rope. The traction rope bears all the weight of the elevator, and in the operation of the elevator, it bends in one direction or alternately around the traction wheel, guide wheel or anti rope wheel. The steel rope also bears high specific pressure in the rope groove, so the steel rope must have high strength, flexibility and wear resistance. This paper analyzes the main factors affecting the fatigue life from the installation, use, maintenance and production process of the steel rope.

The steel rope is a load-bearing element in the elevator, which almost bears all the weight of the elevator. The quality of the steel rope will directly affect the safety of the elevator operation. In the operation of the elevator, the wire rope is bent unidirectionally or alternately around the traction wheel, guide wheel and anti rope wheel. The steel wire rope bears high specific pressure in the rope groove, so the steel wire rope for elevator is required to have high strength, flexibility and wear resistance.

The steel rope is generally circular strand structure, which is mainly composed of steel wire strand and rope core. Steel wire is the basic component of wire rope, which requires high strength and toughness. The strand of wire rope is made of steel wire, usually 8 to 9 strands. The core is usually made of sisal fiber or synthetic fiber of alkene.

The factors affecting the service life of steel rope for elevator mainly include the following aspects: safety factor of traction steel wire rope, tensile load of steel rope, bending radius of steel rope in use, material and groove type of traction wheel, material and twisting quality of steel wire rope itself, lubrication of steel wire rope, use and maintenance of wire rope, etc.

1. Safety factor of traction wire rope

The safety factor of elevator partly depends on the safety factor of traction wire rope. There are static and dynamic loads in the operation of elevator wire rope, but the main factor affecting the service life of steel wire rope is static load. In practical application, in order to simplify calculation, only static load is considered for practical calculation. The diameter of steel wire rope for elevator is very important. In order to improve the strength of steel wire rope and prolong its service life, the diameter of steel wire rope must be the most appropriate size. For the calculation of safety factor, the corresponding safety factor is calculated according to the national approved standard by selecting the diameter of steel wire rope, so as to ensure the safety performance of steel wire rope for elevator The service life of the rope.

2. Tensile load of steel rope

The tensile load is the load that the elevator wire rope bears in the operation of the elevator and the variation in its movement. In a well maintained and debugged elevator, the load of each steel rope in the operation process should be basically the same. If the tension of each rope is uneven in operation due to improper maintenance of the wire rope, the compressive stress between one or several wire ropes and the wheel groove will be greatly increased, which will accelerate the wear of the wire rope and directly affect the service life of the wire rope. Therefore, it is clearly stipulated in the elevator supervision and inspection rules that the deviation between the traction wire rope tension and the average value is not more than 5%.

3. Bending radius of steel rope in use

The curvature radius of steel rope is determined according to the pitch diameter and relative position of traction wheel, anti rope pulley and guide wheel in the use of steel wire rope. Different positions and different pitch diameter determine the bending times and bending stress of steel wire rope in use. The bending stress is inversely proportional to the pitch diameter of each wheel. Article 9.2.1 of gb7588-1995 < Safety Code for elevator manufacture and installation > > stipulates that the ratio of pitch diameter of traction wheel, pulley or drum to the nominal diameter of suspension rope shall not be less than 40 regardless of the number of strands of steel wire rope. During the bending process of steel wire rope, the relative displacement of steel wire in the strand occurs, and there is wear inside. The greater the bending stress, the greater the contact stress between strands With the accumulation of time, the steel wire will break because of stress concentration. Therefore, under the condition that the traction capacity is satisfied, the radius of curvature should be increased as much as possible, the number of rope wheels should be reduced, the reverse bending or twisting of wire rope should be avoided, and the bending stress of steel rope should be reduced in the process of using, so as to reduce the adverse factors on the service life of wire rope.

4. Traction wheel material and groove type

4.1 the groove type and material of traction wheel are closely related to the service life of steel rope. Generally speaking, the wear of steel rope should be very slow due to its higher hardness than rope operation. However, due to the matching of the rope tension and groove type, the elevator wire rope slips, eccentric wear and roll in the groove, which causes wear with the rope groove. Generally, there are semicircular groove, semicircular groove with notch and V-groove. The contact area between the semicircular groove and the rope is relatively large, the specific pressure distribution of the wire rope in the groove is more uniform, and the wear of the rope is relatively small. In order to limit the deterioration of traction conditions due to wear, the lower part of traction wheel is often cut when the rope groove is not subject to additional hardening treatment. The specific pressure distribution of steel rope in the semicircular groove with notch is relatively concentrated, and the specific pressure increases when the notch angle increases. However, due to the small contact area between V-groove and steel wire rope, the specific pressure distribution of steel rope in the rope groove is relatively concentrated, the V-shaped angle is reduced, the specific pressure is increased, and the damage to the steel wire rope is greater in use, which affects the service life of the wire rope.

4.2 generally, the hardness and elastic modulus of the groove should be considered for the material of traction wheel. If the material with soft material is used, the external stress will be reduced, but the wear of the steel wire rope will turn to the inside of the wire rope, and the fracture of the steel wire inside the wire rope will increase. Therefore, it is suggested to use polyurethane rope groove liner on the traction wheel. The liner is embedded into the corresponding groove, and transverse grooves are processed on the liner. The friction coefficient of the appropriate grooved wheel to the non lubricated steel wire rope is almost unchanged, and the polyurethane wear resistance is also very good, which improves the service life of the liner and greatly increases the service life of the elevator wire rope.

5. Steel rope itself

Fatigue is one of the main reasons for more broken wires in the process of using elevator wire rope. The broken wire of elevator wire rope moving around traction wheel is the result of bending fatigue and wear fatigue. The research and understanding of the production process and fatigue essence is helpful to take measures in the production process, improve the fatigue resistance of elevator wire rope and prolong the service life of elevator wire rope It can reduce the operation cost and improve the safety and reliability of elevator operation.

5.1 effect of rope making steel wire

The best metallographic structure is suitable for drawing steel wire. In the production process, due to the surface damage of steel wire, or serious scratches, scars, rust pits, and non-metallic inclusions formed in the steel smelting process, it is easy to form fatigue sources. The content and particle size of non-metallic inclusions in steel have a significant impact on the fatigue performance of steel rope, because the reticular ferrite in the metallographic structure after sorbite can promote the rapid propagation of fatigue crack, so the network ferrite is not allowed in lead quenched steel wire. The austenitizing temperature of steel wire and the isothermal transformation temperature of lead quenching determine the generation of network ferrite Qualitative influence, the automatic control furnace temperature and lead temperature technology of lead quenching production line is conducive to the uniformity of sorbite structure, and the lead liquid circulation is conducive to the uniform sorbite structure of steel wire at different positions in the lead pot, which can ensure that the strength of steel wire after lead quenching is relatively uniform, so as to ensure the minimum fluctuation range of mechanical properties of steel wire after drawing. The optimum combination of strength and toughness is beneficial to improve the fatigue resistance of wire rope. Generally, straight wire drawing machine and water box drawing machine belong to non torsion drawing, which is beneficial to obtain high strength and high toughness steel wire. The lubrication and cooling capacity of water tank is better than that of dry wire drawing machine. Larger diameter drum and tower wheel can reduce the bending deformation of steel wire winding. Multi pass low compression ratio drawing can obtain high toughness.

5.2 selection of steel rope structure

The structure of wire rope has an important influence on the fatigue resistance of steel rope. Generally, surface contact steel rope is caused by line contact wire rope, and wire contact wire rope is caused by point contact wire rope. For the steel rope for elevator, due to the limitation of service conditions and the relatively narrow space environment of elevator shaft, the traction wheel with larger diameter cannot be selected. The rigidity and flexibility of surface contact wire rope are large, because the elevator wire rope produced by forging, die drawing or rolling is rarely used. 6-strand or 8-strand wire contact wire rope is used for ordinary elevator rope, and parallel twisted wire rope is used for high-speed elevator. According to the design concept of modern steel steel rope, it is beneficial to improve the fatigue resistance of steel rope to keep proper gap between strands and layers of steel rope, but the gap between strands and ropes must be uniform. Therefore, it is very important to determine the wire diameter ratio, wire diameter tolerance and hemp core diameter.

5.3 selection of steel rope grease

The quality of grease used in steel wire rope has an important influence on the fatigue resistance of steel rope. It must be selected according to the use and environment of steel rope and the technical index of grease. The elevator wire rope is mainly used in the indoor elevator shaft. When the elevator shaft does not take temperature and humidity control measures, the internal environment of the elevator shaft is closely related to the overall environment of the area, such as low temperature and dry in the northeast, high temperature and humidity in the southern coastal area. The regional temperature and humidity are very different, so the use of steel wire rope end users must be considered when selecting grease The effect of temperature on the physical properties of oil is obvious. The lubricity of the steel wire rope should be kept as long as possible. The grease has certain high and low temperature performance. Generally, the high temperature performance is measured by the drop point of the grease, and the low temperature performance is measured by the low temperature brittleness of the grease. The selected grease should ensure that the high temperature does not drip and the low temperature does not embrittlement.

5.4 oil application method and quantity of elevator rope

In the production process of elevator wire rope, the oiling of rope strand can be generally divided into wire oiling, strand oiling and rope oiling, and the oiling methods can be divided into immersion type and spray type. According to the purpose of the production of steel wire rope to determine the oiling method, but must ensure that the oil evenly distributed on the surface of the steel wire, at the same time for the physical properties of the selected grease, twisting speed to determine the oil content to meet the requirements. Generally, too high oil temperature will lead to grease denaturation, too large amount of oil will reduce the friction between the wire rope and the traction wheel, which is easy to throw out in the process of use; too small amount of oil will reduce the lubrication performance of the wire rope and reduce the fatigue resistance of the wire rope.

5.5 selection of rope core

Most of the steel rope of elevator adopts fiber core structure, and few of them use metal core. The main function of the rope core is to support the rope strand to keep its original shape in any state. Secondly, the rope core can store grease. In the process of use, the oil source for long-term lubrication of the steel wire rope can make the steel wire well lubricated. In addition, it can improve the contact between steel wire strands and wires and reduce the impact load. Therefore, the performance of the rope core has an important impact on the service performance of the wire rope. If the rope core is too thin, the diameter of the wire rope will be reduced, and a certain gap can not be maintained between the strands; if the rope core is too thick, the diameter of the wire rope will increase and the gap between the strands will be generated; if there is a large hemp core joint, the wire rope will bulge, and the contact between the wire rope and the rope wheel will wear quickly due to stress concentration, resulting in wire breakage and strand breakage, so as to ensure the straightness of the rope core Diameter accuracy and joint control are very important. It is one of the ways to prolong the bending fatigue life of the steel wire rope by using the wire rope with high elastic core to reduce the contact stress between the strands when the wire rope bears the bending stress on the rope pulley.

5.6 Steel rope twisting process

The quality of Steel rope twisting directly affects the fatigue life of steel wire rope. The following mainly analyzes the selection and use of twisting process parameters.

5.6.1 selection of lay length

Lay distance is a very important parameter in the technical index of steel wire rope, which has a great influence on the comprehensive performance of wire rope. The size of lay distance directly affects the production efficiency of steel wire rope, the strength loss in the process of steel wire twisting, the breaking force of the whole rope, the flexibility, looseness, fatigue resistance, pressure resistance, impact resistance, structural elongation and diameter of steel wire rope. Therefore, the choice of lay distance should not be too large or too small, and the comprehensive influence of various factors should be considered.

5.6.2 use of tooling

Pre deformer and post deformer are the main fixture for wire rope production. The design of main process parameters is generally based on wire rope diameter, strand diameter and experience

According to the formula, in order to make the parameters more reasonable and scientific, combined with practical production experience and the strength level of wire rope, the process parameters are formulated respectively.

5.6.3 use of pretensioning

The main purpose of wire rope pretensioning is to partially or completely eliminate the structural elongation of steel wire rope that cannot be completely avoided in use. Proper pre tensioning treatment can eliminate the twisting defects of steel wire rope, improve the uniform distribution of tension of steel wire and wire rope strand when bearing, make the strand rope in the most stable position in structure, which is conducive to improve the fatigue strength of steel wire rope and prolong the wire rope Service life.

6. Lubrication of Steel rope

The lubrication of elevator rope can effectively reduce the friction of steel wire rope and prolong the service life of steel wire rope. Generally speaking, in the applicable places with large diameter of traction wheel and dry temperature, the steel wire rope still has enough lubricating oil after using for 3 to 5 years, and it is not necessary to add new oil. However, no matter how long it is used, maintenance lubricating oil must be added as long as rust or drying signs occur on the elevator wire rope.

7. Use and maintenance of elevator rope

The use and maintenance of elevator rope is to effectively maintain the steel wire rope after the completion of elevator installation, mainly from the following four aspects of maintenance and replacement, to ensure the safe use of elevator rope, and achieve the expected service life.

7.1 during the operation of the elevator, timely and regularly check the operation condition of the steel wire rope, mainly including the number, position and twist distance of the steel wire rope; the thinning of the wire rope diameter; the uniform tension of the wire rope; the lubrication, cleaning and corrosion of the steel wire rope; whether the assembly of the steel wire rope end has elongation or abnormal conditions.

7.2 observe the wear and deformation of the elevator wire rope during operation, and confirm whether to replace it with a new one. The phenomenon of sudden fracture of elevator wire rope under normal working conditions is rare, and its damage is generally formed in long-term operation due to wear, bending fatigue, corrosion or external damage, so timely observe the abnormal phenomenon of steel wire rope in operation to avoid unnecessary safety factors.

7.3 for the condition of elevator wire rope in rope groove, check whether the working surface of rope groove is smooth and whether the depth of steel wire rope lying in rope groove is consistent.

7.4 corrosion inspection of elevator wire rope: the elevator steel wire rope will rust during the use process, the mechanical properties will be reduced, the diameter of steel wire will become thinner, and the strands will be loose, resulting in brittle fracture. This kind of fracture is avalanche fracture, which is more dangerous than general wire breaking or wear. Regular addition of maintenance lubricating oil is a way to prevent wire rope corrosion.

Conclusion: as the most important part of elevator suspension device, elevator wire rope plays an important role in the safety performance of elevator. In the production process, the design of process parameters and the control of production process have a crucial impact on the fatigue resistance of steel wire rope. Taking measures against these factors can improve the fatigue resistance of wire rope. In the use of elevator wire rope, the correct installation and maintenance can also extend the service life of steel rope.

LKS elevator wire rope recommands;

Our elevator rope wire is made from bright phosphated and redrawn galvanized wires. They are designed for use in traction- and deflection sheaves. Featuring high tensile strength and excellent ductility, the wire helps increase the service life of your rope. Meets EN-10264-2 specifications. The wire is customizable to your project.

Assuring your performance

Bekaert has a full range of elevator rope wire of bright phosphated and redrawn galvanized wires. They are ideal for the creation of elevator ropes because of their high tensile strength and excellent ductility. On the rope level, these properties lead to optimal fatigue performance. The wire can increase the service life of your rope and reduce your rope’s maintenance.

Meeting your requirements

The smooth coating surface of the wire, and the adapted packing they come in, helps your production process run smoothly. They are suitable for double-twist stranding machines. Bekaert elevator rope wire meets the standard EN-10264-2 specifications. Our global team of experts can also help customize the properties to your specific requirements.

Creating a reliable tension member

The quality of the steel wires used for elevator cores has a substantial impact on the service life of the rope. When running over the traction- and deflection sheaves, the wires in the rope are exposed to high tension- and flexural stresses, causing friction which will result in abrasive wear. Our elevator rope wire’s excellent mechanical properties are a solution for these issues.

Elevator Steel Wire Ropes with FC & IWRC

Steel wire ropes are one of the best choices for elevator applications owing to its two main features: redundancy and detectability as shown below:

- Redundancy is very important for safety-relevant applications. If one of individual elements is broken, other elements will take on its function and remain in operation taking advantages of interaction between wires.

- Detectability means the capacity to determine the end of service life and the degree of bending fatigue of running wires. As fatigue increase, more external wire breaks so that it is possible to estimate by visible inspection before the condition becoming dangerous.

Normally, elevator wire ropes feature parallel strand construction for reducing incidence of abrasion compared with ropes with cross laid construction. Meanwhile, they have a high fatigue bending life and less wear to running sheaves.

Construction:

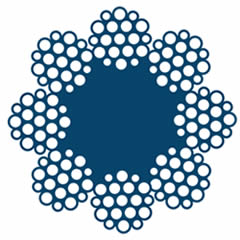

Depending on the intended needs, two different core types are available: fiber core (FC) and independent wire rope core (IWRC).

- Fiber core, made of natural or synthetic fibers, is widely used in ropes and makes elevator ropes easier to adjust up to the relevant groove shape. Meanwhile, fiber core provides excellent resistance against contact pressure and long-term support for elevator wire ropes.

- Independent wire rope core effectively increases the metallic cross-section of elevator wire ropes and reduce tensile stress in individual wires. Meanwhile, steel cores low the elongation of elevator wire ropes under same loads compared with fiber core.

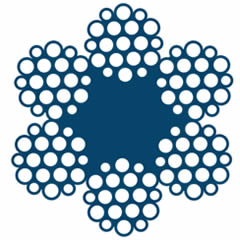

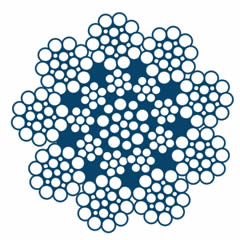

Normally, an elevator wire rope is composed of six, eight or nine strands with FC or IWRC as shown in the following pictures:

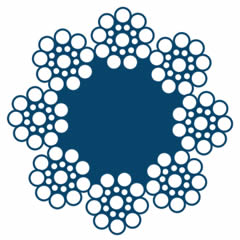

Standard elevator wire ropes with FC

6 × 19 FC & Warrington

6 × 25 FC & Filler wire

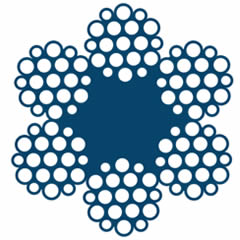

8 × 19 FC & Warrington

8 × 19 FC & Seale

8 × 21 FC & Filler wire

8 × 25 FC & Filler wire

Six strands FC style:

- Large metallic cross section for high breaking loads.

- Relatively lower elongation.

- Competitive price per meter.

- Ideal for slow traveling freight elevators.

- Suitable for low-duty passenger elevators.

Eight strands FC style:

- Rounder cross section than six strands ropes.

- Favorable contact pressure condition.

- Flexible cross section for easier adjustments to worn grooves.

- Thinner wires offer better fatigue bending property.

- Medium price per meter.

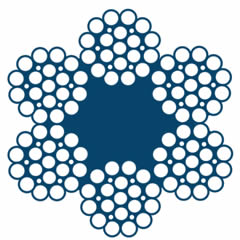

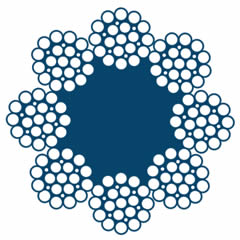

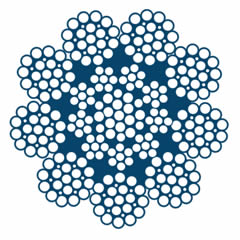

8 × 19 IWRC & Warrington

8 × 19 IWRC & Warrington

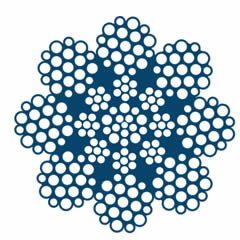

9 × 21 IWRC & Filler wire

9 × 25 IWRC & Filler wire

9 × 25 IWRC & Filler wire

Eight strands IWRC style:

- Rounder cross section than six strands ropes.

- Suitable for grooves with a large undercut.

- Little or no permanent and elastic elongation.

- More flexible structure offers better fatigue bending property.

- Ideal for heavy-duty elevators

Nine strands IWRC style:

- Offer an extremely round cross section

- Low contact pressure between rope and groove.

- Minimal permanent and elastic elongation.

- Much thinner wires offer better fatigue bending property.

- Ideal for all elevators with large shaft height.

- Suitable for traction drive elevators with a larger number of deflection sheaves.

Details:

- Material: quality bright steel wires, galvanized steel wires or stainless steel upon request.

- Nominal tensile strength: 1370N/m2, 1570N/m2, 1770N/m2 up to 2500N/m2 as your request.

- Cable diameter: 1/4″ to 3/4″ or custom diameters.

- Structure: parallel laid structure.

- Packing: in coils wrapped with oil paper and hessian cloth or on wooden reels.

- Core: FC or IWRC.