It is the largest lifting weight of single equipment in China,Wire Rope Sling is made by LKS.

Core Abstract: on June 10, the world’s first 3000 ton slurry bed residue hydrotreating reactor, which was hoisted by Sinopec heavy lifting and Transportation Engineering Co., Ltd. and cooperated with the 10th Construction Company, was successfully hoisted in place after 15 hours, which refreshed the overall hoisting weight of a single domestic equipment. The super slurry bed reactor with the heaviest monomer in the world, No. 2141-r-200lc, is the reactor with the largest monomer tonnage in the world. The equipment has a unit weight of 3025 tons, a total length of 72 meters, an outer diameter of 6.156 meters.

On June 10, the world’s first 3000 ton slurry bed residue hydrotreating reactor, which was carried out by Sinopec heavy lifting and Transportation Engineering Co., Ltd. and cooperated with the 10th Construction Company, was successfully hoisted in place after 15 hours, refreshing the overall hoisting weight of a single domestic equipment.

The super slurry bed reactor with the heaviest monomer in the world, No. 2141-r-200lc, is the reactor with the largest monomer tonnage in the world. The unit weight of the equipment is 3025 tons, the total length is 72 meters, the outer diameter is 6.156 meters, and the wall thickness is 320 mm. It is the core equipment of Zhejiang Petrochemical 40 million tons / year refining and chemical integration phase II project.

The hoisting scheme of 5200t hydraulic lifting system main crane and 2000t crawler crane tail sliding is adopted.

The 5200t hydraulic lifting system has the following advantages: the hoisting capacity is large, which can minimize the impact on the construction site; it has the function of overall displacement and reduces the disassembly and assembly steps of the intermediate tower, so as to shorten the overall construction period.

After the reactor 2141-r-200lc was transported from the wharf to the site, the project Department of the second phase project of Zhejiang Petrochemical Company of the tenth construction company worked overtime to complete the preparation for the installation of the reactor cover and equipment.

At 9:17 am on June 9, the lifting of super slurry bed reactor started on time…

At 8 am on June 10, the hoisting of 2141-r-200lc reactor continued…

At 11:27 am on June 10, the reactor with the largest monomer tonnage in the world was hoisted in place! The whole process is safe and stable.

After the hoisting, the 5200t hydraulic lifting system will move as a whole to prepare for the hoisting of the second reactor 2141-r-200lb…It’s just a beginning…

If we read this article carefully,you will find there is a very important thing-lifting & hoisting!We should take carefully about the lifting,all things should be considered espcially about the breaking load of lifting slings.For such big liftings,we use 7:1 safety factor to satisfy with the lifting demands.LKING STEEL LIMITED joined in this lifting design and manufacture wire rope sling.

Here is some technical information from LKING STEEL LIMITED as your reference;

Product features

- Wire rope slings for lifting loads in industrial environments

- 6 x 37 IWRC (independent wire rope core) construction for greater flexibility than a 6 x 7 or 6 x 19 wire rope sling

- Eye-and-eye endings for vertical, choker, and basket lifting configurations

- Mechanical (also called Flemish) splice is stronger than a hand splice

- Meets ASME specification B30.9 and OSHA specification 1910.184

Product description

The LKING STEEL LIMITED 6 x 37 IWRC (independent wire rope core) single-leg wire slings have eye-and-eye endings and a mechanical splice for lifting loads with vertical, choker, or basket configurations in general industry applications. The 6 x 37 IWRC construction contains six strands of wire rope with approximately 37 wires per strand wrapped around a separate 7 X 7 wire rope, which has seven strands with seven wires per strand, in the center of the sling. This construction provides more flexibility than a 6 x 7 or 6 x 19 wire rope slings. The wire rope construction has more abrasion and heat resistance than a web sling. This eye-and-eye sling has an eye, or loop, on both ends, and can be used with vertical, choker, and basket lifting configurations. The eyes are secured with a mechanical (also called Flemish) splice that is stronger than a hand splice. This sling has a minimum D/d ratio of 25 and meets American Society of Mechanical Engineers (ASME) specification B30.9 and Occupational Safety and Health Administration (OSHA) specification 1910.184.

Slings are used to lift heavy objects for industrial applications. Types of slings include web slings, wire rope slings, chain slings, and mesh slings. The appropriate type of sling for an application depends on the strength-to-weight ratio, flexibility and resistance to bending, resistance to abrasion and cutting, resistance to crushing, resistance to stretching, and resistance to high temperatures and other environmental stressors. Slings have one, two, three, or four legs; or a continuous loop of webbing or wire rope. Legs are support branches that extend from a single point at the top of the sling to the item being lifted so the weight of the load is distributed evenly among the branches. Slings have eyes (loops) or alloy steel fittings on the ends.

A vertical lifting configuration connects a crane hook directly to a load with a single, vertical sling, usually by means of a hook. In a choker configuration, the sling wraps entirely around the load, and one loop passes through the other to form a slip noose, or choker. In a basket configuration, the sling passes under the load and both ends of the sling connect to the crane hook. Load capacity is the maximum weight to be lifted in a vertical configuration. The capacity in a choker configuration is approximately equal to the vertical capacity times 0.8. The capacity in a basket configuration, with sling ends at a 90-degree angle, is approximately equal to twice the vertical capacity. Load capacity in a basket configuration decreases if the angle of the sling is less than 90 degrees. For example, a sling with a capacity of 2,000 lb. in a vertical configuration will have an approximate capacity of (2,000)(0.8)=1,600 lb. in a choker configuration and an approximate capacity of (2,000)(2)=4,000 lb. in a basket configuration, if the sling ends are at a 90-degree angle to the load. A wire rope sling’s capacity in a basket configuration applies only when the configuration meets the sling’s minimum D/d ratio, which is the ratio of the diameter of the rope’s curve around the load (D) to the diameter of the sling (d). If the minimum D/d ratio is not met, the capacity of the sling is decreased.

LKING STEEL LIMITED Lifting Technologies manufactures lifting solutions including slings, cranes, and hoists. Founded in 1967, the company is headquartered in Shanghai, China.

Attention for lifting

A) if a single leg cable sling, the hanging point must be located directly above the center of gravity of the suspended object.

B) if the 2legswire rope sling, the hanging points should be on both sides of the goods and the hooks are above the center of gravity of the suspended objects.

C) if it is three legs or four legs wire rope sling, the hanger must be proportioned on the plane around the cargo and the hook is located directly above the center of gravity of the suspended object.

Pressed Steel Wire Rope Slings

- ZL 2006 3 0000330.7

- This specification of the wire rope used for the working load: from 6mm to 60mm with construction 6 x37 type b-1670.

- Different construction of the rope means different working load, we can calculate the working load according with the steel wire rope construction which the customer required.

- The sling’s breaking load is 5 times of the working load.

- When the wire rope diameter is up to 90mm, should be pressed two aluminum alloy joints on each end of sling.

- We use one aluminum ferrule painted with the blue color as the quality ID of LKS Sling.

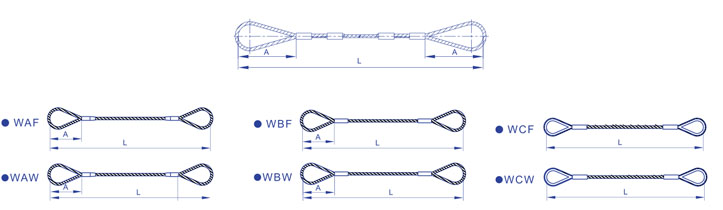

Wire rope sling specification

| Art. No. | Dia. of Rope (mm) | Working Load Limit | Approx. Eye Length A (mm) | ||||||

| FC | IWRC | FC(kn) | IWRC(kn) | ||||||

| WAF06 | WBF06 | WCF06 | WAW06 | WBF06 | WAW06 | 6 | 3.2 | 3.4 | 180 |

| WAF07 | WBF07 | WCF07 | WAW07 | WBF07 | WAW07 | 7 | 4.3 | 4.7 | 190 |

| WAF08 | WBF08 | WCF08 | WAW08 | WBF08 | WAW08 | 8 | 5.7 | 6.1 | 210 |

| WAF09 | WBF09 | WCF09 | WAW09 | WBF09 | WAW09 | 9 | 7.2 | 7.8 | 230 |

| WAF10 | WBF10 | WCF10 | WAW10 | WBF10 | WAW10 | 10 | 8.9 | 9.6 | 230 |

| WAF11 | WBF11 | WCF11 | WAW11 | WBF11 | WAW11 | 11 | 11 | 12 | 250 |

| WAF12 | WBF12 | WCF12 | WAW12 | WBF12 | WAW12 | 12 | 13 | 14 | 260 |

| WAF13 | WBF13 | WCF13 | WAW13 | WBF13 | WAW13 | 13 | 15 | 16 | 260 |

| WAF14 | WBF14 | WCF14 | WAW14 | WBF14 | WAW14 | 14 | 17 | 19 | 280 |

| WAF16 | WBF16 | WCF16 | WAW16 | WBF16 | WAW16 | 16 | 23 | 24 | 320 |

| WAF18 | WBF18 | WCF18 | WAW18 | WBF18 | WAW18 | 18 | 29 | 31 | 360 |

| WAF20 | WBF20 | WCF20 | WAW20 | WBW20 | WCW20 | 20 | 35 | 38 | 400 |

| WAF22 | WBF22 | WCF22 | WAW22 | WBW22 | WCW22 | 22 | 43 | 46 | 440 |

| WAF24 | WBF24 | WCF24 | WAW24 | WBW24 | WCW24 | 24 | 51 | 55 | 480 |

| WAF26 | WBF26 | WCF26 | WAW26 | WBW26 | WCW26 | 26 | 60 | 65 | 520 |

| WAF28 | WBF28 | WCF28 | WAW28 | WBW28 | WCW28 | 28 | 69 | 75 | 560 |

| WAF30 | WBF30 | WCF30 | WAW30 | WBW30 | WCW30 | 30 | 80 | 86 | 600 |

| WAF32 | WBF32 | WCF32 | WAW32 | WBW32 | WCWF32 | 32 | 91 | 98 | 640 |

| WAF34 | WBF34 | WCF34 | WAW34 | WBW34 | WCW34 | 34 | 102 | 110 | 680 |

| WAF36 | WBF36 | WCF36 | WAW36 | WBW36 | WCW36 | 36 | 115 | 124 | 720 |

| WAF38 | WBF38 | WCF38 | WAW38 | WBW38 | WCW38 | 38 | 128 | 138 | 760 |

| WAF40 | WBF40 | WCF40 | WAW40 | WBW40 | WCW40 | 40 | 142 | 153 | 800 |

| WAF42 | WBF42 | WCF42 | WAW42 | WBW42 | WCW42 | 42 | 157 | 169 | 840 |

| WAF44 | WBF44 | WCF44 | WAW44 | WBW44 | WCW44 | 44 | 172 | 185 | 880 |

| WAF46 | WBF46 | WCF46 | WAW46 | WBW46 | WCW46 | 46 | 187 | 203 | 920 |

| WAF48 | WBF48 | WCF48 | WAW48 | WBW48 | WCW48 | 48 | 203 | 220 | 960 |

| WAF50 | WBF50 | WCF50 | WAW50 | WBW50 | WCW50 | 50 | 221 | 240 | 1000 |

| WAF52 | WBF52 | WCF52 | WAW52 | WBW52 | WCW52 | 52 | 239 | 259 | 1040 |

| WAF54 | WBF54 | WCF54 | WAW54 | WBW54 | WCW54 | 54 | 258 | 279 | 1080 |

| WAF56 | WBF56 | WCF56 | WAW56 | WBW56 | WCW56 | 56 | 277 | 301 | 1120 |

| WAF58 | WBF58 | WCF58 | WAW58 | WBW58 | WCW58 | 58 | 298 | 322 | 1160 |

| WAF60 | WBF60 | WCF60 | WAW60 | WBW60 | WCW60 | 60 | 319 | 345 | 1200 |

| — | WBF62 | — | — | WBW62 | — | 62 | 290 | 343 | 1240 |

| — | WBF64 | — | — | WBW64 | — | 64 | 309 | 365 | 1280 |

| — | WBF66 | — | — | WBW66 | — | 66 | 329 | 389 | 1320 |

| — | WBF68 | — | — | WBW68 | — | 68 | 349 | 413 | 1360 |

| — | WBF70 | — | — | WBW70 | — | 70 | 370 | 437 | 1400 |

| — | WBF72 | — | — | WBW72 | — | 72 | 391 | 463 | 1440 |

| — | WBF74 | — | — | WBW74 | — | 74 | 413 | 489 | 1480 |

| — | WBF76 | — | — | WBW76 | — | 76 | 436 | 516 | 1520 |

| — | WBF78 | — | — | WBW78 | — | 78 | 459 | 543 | 1560 |

| — | WBF80 | — | — | WBW80 | — | 80 | 483 | 571 | 1600 |

| — | WBF82 | — | — | WBW82 | — | 82 | 507 | 600 | 1640 |

| — | WBF84 | — | — | WBW84 | — | 84 | 532 | 630 | 1680 |

| — | WBF86 | — | — | WBW86 | — | 86 | 558 | 660 | 1720 |

| — | WBF88 | — | — | WBW88 | — | 88 | 584 | 691 | 1760 |

| — | WBF90 | — | — | WBW90 | — | 90 | 611 | 723 | 1800 |

| — | WBF92 | — | — | WBW92 | — | 92 | 639 | 756 | 1840 |

| — | WBF94 | — | — | WBW94 | — | 94 | 667 | 789 | 1880 |

| — | WBF96 | — | — | WBW96 | — | 96 | 695 | 823 | 1920 |

| — | WBF98 | — | — | WBW98 | — | 98 | 725 | 857 | 1960 |

| — | WBF100 | — | — | WBW100 | — | 100 | 755 | 893 | 2000 |

| — | WBF102 | — | — | WBW102 | — | 102 | 785 | 929 | 2040 |

| — | WBF104 | — | — | WBW104 | — | 104 | 816 | 966 | 2080 |

| — | WBF106 | — | — | WBW106 | — | 106 | 848 | 1003 | 2120 |

| — | WBF108 | — | — | WBW108 | — | 108 | 880 | 1041 | 2160 |

Approx. eye length A is not applicable to the WCF and WCW series.